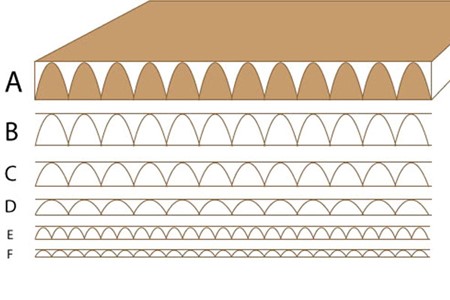

A-Flute, the original flute, is the highest flute size, and therefore, when combined with an inner and outer facing, is the thickest. With 36 flutes to the foot, A-Flute makes the most of corrugated's cushioning and stacking properties for fragile and delicate items. Because A-Flute offers excellent stiffness qualities and short column crush resistance, it has a broad range of uses.

DIFFERENT TYPES OF

FLUTES IN CORRUGATED BOXES

For thousands of years, architects have known that an arch with a proper curve is the best and strongest way to span any given space. When corrugated boxes began to be manufactured, they used these same principles to the paper medium. These arches, which are commonly referred to as flutes, are adhered to the outer sheets (linerboard) with a starch based adhesive and are resistant to bending and pressure from all directions. The "Flute" describes the structure of the wave shaped cardboard material that makes up a board's corrugation. Flutes come in several sizes, known as flute profiles. The standard profiles range from A-flute (the largest) to F-flute and below (microflutes).Flutes determine the different thicks and thins of corrugated as well as strengths. Flutes are typically measured by A, B, C, D, E & F. The flutes are sandwiched between the linerboard's. As you can see from the illustration the flutes are thickest at grade A. and compact more and more up until F

Generally, larger flutes provide greater strength and cushioning, while smaller flutes have better printability and foldability. Flute profiles can be mixed and matched within a single piece of combined board. CE double wall is durable because of its C-flute layer, while its E-flute layer provides a smooth printing surface. A sheet of material can be made of different thickness of board to manipulate printability, compression and cushioning strengths.

B-Flute, the second flute size adopted by the corrugated industry, has lower arch heights than A and more flutes per foot (49). This means that the medium contacts and supports the liners at a greater number of points, providing a stiff, flat surface for high quality printing and die cutting and with excellent crush resistant properties. B-Flute is also preferred for high speed, automatic packing lines and for pads, dividers, partitions and other forms of inner packing. Complex die cuts and beverage trays are excellent applications for B-Flute as are can cases, wrap-around blanks, glass-to-glass packs and slipsheets. B-Flute is generally combined with lightweight liners but can be used with heavier facings if the need arises. Common uses are food packaging, retail packaging, litholaminating, POP (point of purchase) displays, die cut inserts, and custom printed packaging.

B-Flute, the second flute size adopted by the corrugated industry, has lower arch heights than A and more flutes per foot (49). This means that the medium contacts and supports the liners at a greater number of points, providing a stiff, flat surface for high quality printing and die cutting and with excellent crush resistant properties. B-Flute is also preferred for high speed, automatic packing lines and for pads, dividers, partitions and other forms of inner packing. Complex die cuts and beverage trays are excellent applications for B-Flute as are can cases, wrap-around blanks, glass-to-glass packs and slipsheets. B-Flute is generally combined with lightweight liners but can be used with heavier facings if the need arises. Common uses are food packaging, retail packaging, litholaminating, POP (point of purchase) displays, die cut inserts, and custom printed packaging.

E-Flute has the greatest number of flutes/foot,which gives it the greatest crush resistance and the flattest surface for high quality printing applications. The thin board profile of E-Flute (it is one-fourth the thickness of C-Flute) reduces box size and saves storage space. Because of its thin profile and cushioning properties, E-Flute can substitute for conventional folding cartons or solid fiber containers. Examples of E-Flute applications include boxes for cosmetics, glass, ceramic items and delicate instruments. Another growing end-use is the pizza box: a cost effective, printable container for product protection.

F-Flute, the newest flute, is nearly half the thickness of E-Flute and is a popular choice in the corrugated industry. The idea for F-flute originated in Europe to reduce the fibre content of packaging. Converting to F-Flute can reduce the total amount of fibre in packaging. F-flute makes a more rigid box and sends less wastage. F Flute will give your box a very high value look and provide your packaging with solid structural integrity. Common uses are custom printed boxes, printed corrugated boxes, retail packaging, and POP displays. So, we can see that corrugated packaging has evolved with the time and new "FLUTE" types that have emerged with time have provided a great deal of flexibility to the corrugated industry. This has helped corrugated products being adopted to pack a wide range of products and will continue to do so in future.

The custom regular slotted carton is one the most common custom packaging boxes on the market. They are easily assembled, the flaps can be taped shut. For strength and durability these can be made into many different types of custom flutes and wall construction (or thickness) combinations.

The custom AFM is a very strong box due to the fact that all flaps meet at the center creating a double layer of the thickness of the custom corrugated board.

The flaps on the custom FOL box extend from one side to the other, making it an excellent custom box for heavy objects or rough handling.

The bottom is the same as a custom RSC box but custom half slotted carton has no top flaps. These custom boxes can be provided with a lid for a top cover. Typical applications include: part bins, file folder boxes, storage boxes etc

The custom roll end tuck top is an unglued box that needs to be folded when assembled. The sides are 3 layers of custom corrugated for added strength and the top opens and closes with a tuck to the inside of the box. You can also add dust flaps and cherry locks for added stability.

Same as a STE but the ends tuck and lock on opposite panels.

The custom sameside tuck end is a box glued with each end folding and locking on the same side. The custom STE can give you a better graphic presentation if the tucks are on the back of the box. A fifth panel can be added for hanging on pegs and giving additional space for custom packaging graphics.

Designed for quick set up, the custom tucktop auto bottom box is pre-glued on the bottom. This allows the box to be loaded with product without additional folding or taping. The top of the box is then closed by tucking in the top. The top can have an additional locking tab called a catalog lock or locking tab. Club stores normally like a security label for additional protection. This custom corrugated box can also have a cut-out in the front panel to show your product inside.